Sustainability

The lightweight metal construction products are helping you create buildings that tackle the sustainability challenges of the future.

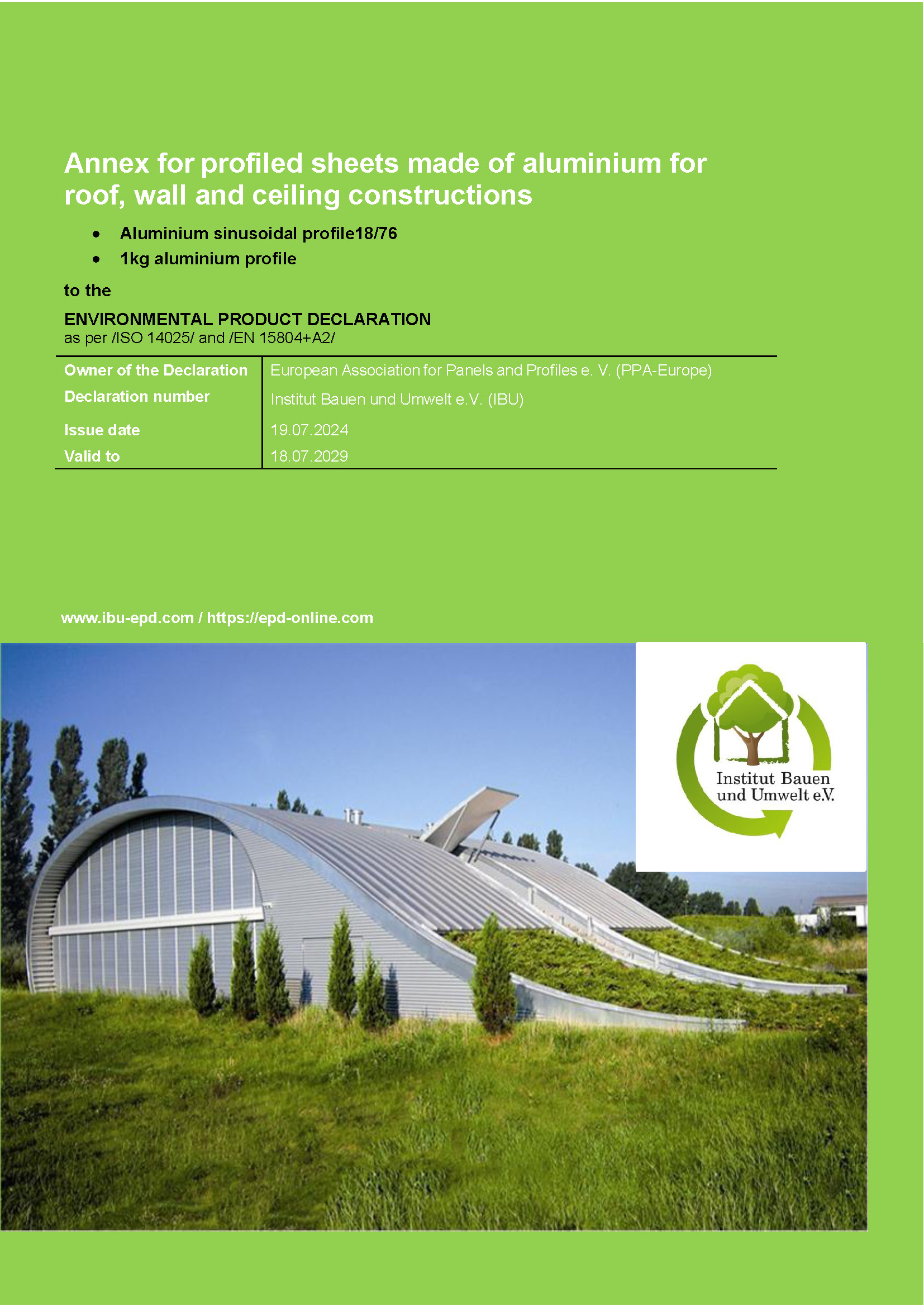

1. Circularity

The lightweight metal construction products are contributing to circular buildings.

2. Energy Efficiency

The lightweight metal construction products are reducing the energy demand in buildings.

3. Embodied Carbon

Our manufacturers are making efforts to reduce the embodied carbon in their products.

Sustainable solutions

- Metal faced sandwich panels and metal profiles have a lifespan of at least 50 years.

- Panels and profiles are reused in buildings.

- The use of steel scrap in steel production reduces CO2 emissions by 58%.

- Fossil-free steel and aluminium are already available and the standard of the future.

- Recycled aluminium only needs 5% of the energy compared to primary aluminium.

- Insulation cores are recycled to get new insulating products.

Sustainable development in the economic, social and environmental sectors is influenced to a considerable extent by the building sector. This sector is the focus of political attention, particularly in the area of ecology, due to its large share of energy and material flows, so that life cycle assessment has become an integral part of the sustainability assessment of buildings. The building envelope, which is predominantly constructed with lightweight metal building elements, especially in industrial and commercial buildings, can make an important contribution to the sustainability of a building if the construction is designed in accordance with the cycle and the energy quality is high.

For quantifiable assessment of the ecology, Environmental Product Declarations (EPDs) are available for profiled sheets and sandwich elements with information on environmental impacts over the entire life cycle. The methods of Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) can be used as important building blocks of the sustainability assessment to compare aspects of material and resource efficiency of different construction methods. The deconstruction and recycling potential as well as the reusability of the materials of lightweight metal construction have a positive influence on the overall balance.

The energy efficiency of the building envelope also plays a dominant role in the sustainability assessment of buildings, as it has a significant influence on the results of the life cycle assessment. Sandwich elements, for example, are absolutely airtight in the area of the metal face sheets, can achieve very high thermal insulation due to the low thermal conductivity of the thermal insulation material and thus contribute to the construction of energy-efficient and sustainable buildings.

In the future, it will be necessary to optimise the ecological, economic and social qualities of lightweight metal construction, taking into account the entire life cycle. This current task for lightweight construction with metal is summarised here under the term “sustainability”.

Lightweight metal construction products help you construct a sustainable building

Many of the buildings into which lightweight metal construction products are incorporated are energy neutral or even energy producing. This happens because these products possess properties that contribute to the sustainable use of buildings. Besides this, the lightweight metal construction products are suitable for recyclable and removable building. Intrigued as to what properties are responsible for this?

Three properties of sandwich panels that ensure you save energy:

1. A thermal-insulating core

Sandwich panels have core materials with excellent insulating properties. These are available in various thicknesses up to 300 mm.

2. Cold bridges are absent because the inner and outer panel faces are not connected to each other.

This prevents heat leaking away.

3. High-grade sealing strip in the joint for an optimal air seal

Airtight building is easy to achieve with sandwich panels.

These properties ensure perfect insulation.

Building with a surface mount system of liner trays with glass or stone wool insulation would also help achieving an energy neutral or energy producing building.

Recyclable building, removable building or building according to the cradle-to-cradle philosophy?

These three properties of lightweight metal construction products ensure you achieve your goal:

1. Removable building

The products can be attached with screws. This makes them suitable for removal and reuse. During its service life, a building can be modified for another function by relatively simple means. This increases the service life of the building in its entirety. Before sandwich panels are recycled, they are often reused first.

2. Recycling or upcycling

Most of the lightweight metal construction products are made of or contain steel, which is one of the few materials with a true closed recycling loop. Steel is therefore not consumed, but can be reused again and again, without detriment to its quality or strength.

3. Lightweight

Thanks to the low inherent weight of sandwich panels and profiles, both the foundation and the structure can be implemented lighter. This saves still more material.

Further, all lightweight metal construction products are manufactured to the desired size. This means that almost no building waste is generated.

Since 2013, PPA-Europe owns collective Environmental Product Declarations (EPDs) for sandwich panels and profiled sheets produced by its member companies. These EPDs are being updated every five years. The latest update has recently been finalised and a new edition complying with EN 15804+A2 has been published by the EPD programme operator IBU in July 2024. There are four association EPDs, dealing with:

-

double skin steel faced sandwich panels with a core made of mineral wool,

-

double skin steel faced sandwich panels with a core made of polyurethane,

-

profiled sheets made of steel for roof, wall, deck and ceiling constructions,

-

profiled sheets made of aluminium for roof, wall and ceiling constructions.

In the EPDs, average Life Cycle Assessment (LCA) values related to the environmental sustainability are being provided. These are based on input data submitted by the participating memeber companies, as listed on the second page of each EPD. Each of the four EPDs is accompanied by an annex which contain LCA values for further product variations.