About us

Supporting the growth of the business

pushing an open European market

Setting quality standards

European Association for Panels and Profiles (PPA-Europe)

The European Association for Panels and Profiles was established in 2003. It is the “ambassador” of the manufacturers of metal profiled sheets, sandwich panels and ancillary products on the European level, representing them in all political, regulatory, technical committees or any other initiatives which are relevant for realizing a harmonized and free market in Europe. It aims to provide expertise and information to decision makers in this segment of the construction sector, which has high potential with regard to energy efficiency, sustainable construction but also resource efficiency and flexibility of design.

Tasks

Work monitoring and, where necessary, active involvement in different standardization committees and organizations, such as:

- Acting against misleading information on the market towards the customers, by any party, eventually even panel and profile manufacturers;

- Information of the customers about quality aspects;

- Cooperation with other European associations;

- Cooperation with institutes with excellent knowledge on metal sandwich panel and profile technology.

The association does not carry on an economic business.

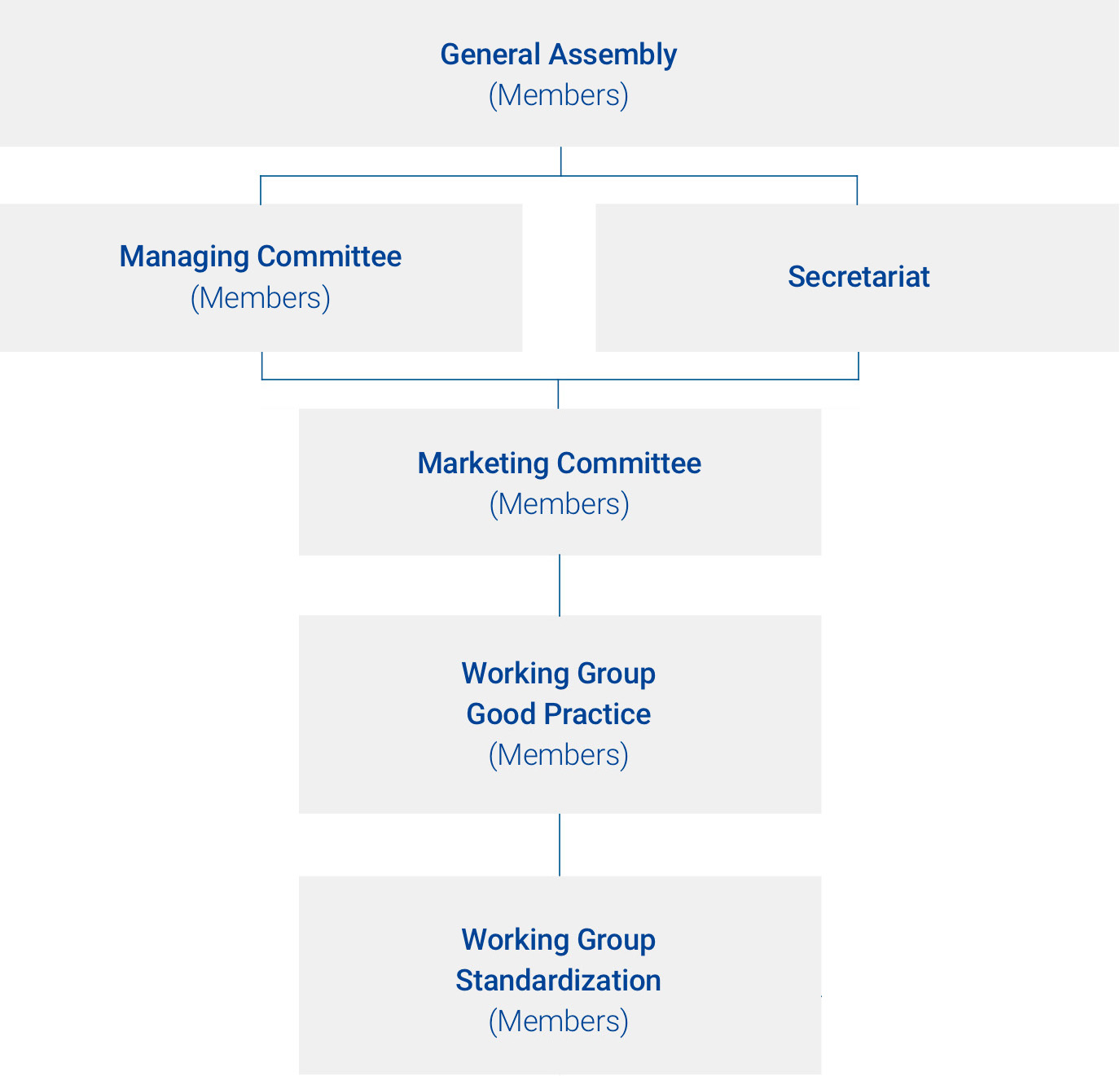

COMMITTEES AND WORKING GROUPS

Managing Committee

Manages the activity of the association.

Only representatives from ordinary association members are allowed in the MC.

Secretariat:

Dr.-Ing. Ralf Podleschny

President: J. C. Kennel

Working Group Good Practice

Has developed (and will probably update) a document of European good practice rules for the work planning and installation of walls (wall cladding) and roofs (roof covering) using metal faced sandwich panels.

Currently dormant

Secretariat:

Daniel Cumpănașu

Working Group Standardization

Forum, in which the members of PPA-Europe get regularly updates on relevant standardization projects and regulation work (e.g. EN 14509, EN 14782, EN 1090 or the new EU Construction Products Regulation).

Meant to be the technical regulatory expert mirror group of the metal sandwich panel and profile industry, which discusses the relevant standardization projects and regulatory initiatives and prepares (technical) input.

Open for (new) participants.

Secretariat:

Daniel Cumpănașu

Chairman:

M. Rippel

Working Group Sustainability

Forum, in which the members of PPA-Europe get regularly updates on:

- sustainability related requirements for the building sector from:

- European initiatives, such as: policies, communications, regulations and horizontal standards, whether with draft status or already adopted and in place (e.g. EU Green Deal, EU Renovation Wave, EU Taxonomy Regulation, EN 15804)

- Building sustainability assessment systems and certification schemes (e.g. DGNB)

- development of European standards for elaboration of Environmental Product Declarations for metal profiles and metal sandwich panels (Product Category Rules complementary to EN 15804)

Meant to be the sustainability expert mirror group of the metal panel and profile industry, which discusses the relevant issues and provide (technical) input.

Open for (new) participants.

Secretariat:

Daniel Cumpănașu

Chairman:

Prof. M. Kuhnhenne

Organization Chart

PRODUCTS

Building with structural elements made from surface finished metal plate has undergone rapid development over the last 40 years. The trapezoidal profiles, corrugated profiles, cassettes and sandwich panels used in numerous office, industrial and public buildings for floors, roofs and walls represent the present-day image of modern architecture. Metals are now the preferred building materials and this is due to their excellent characteristics (load bearing capability, ductility, etc) as well as its relatively cheap price when compared to alternative building materials. The easy assembly and dismantling and especially the reusability (recycling) are other advantages of using structural elements made from metal plate as compared to other building materials.

Trapezoidal profiles, corrugated profiles, cassettes and sandwich panels are characterised by their:

- Functionality

- Flexibility

- Economicalness

- Design capabilities

The European Association for Panels and Profiles has installed an independent and unsolicited quality assurance system in order to be able to supply builders with top quality products, which meet all of the requirements regarding the building of roofs and facades, especially if using the structural elements presented here.

Structural elements made from metal plate provide builders and architects with products, which meet all of the highest demands regarding constructional characteristics and design. Aesthetic, valuable and permanent buildings can be constructed so that meet all of the requirements of a modern structure, especially if built in conjunction with specialised assembly procedures.

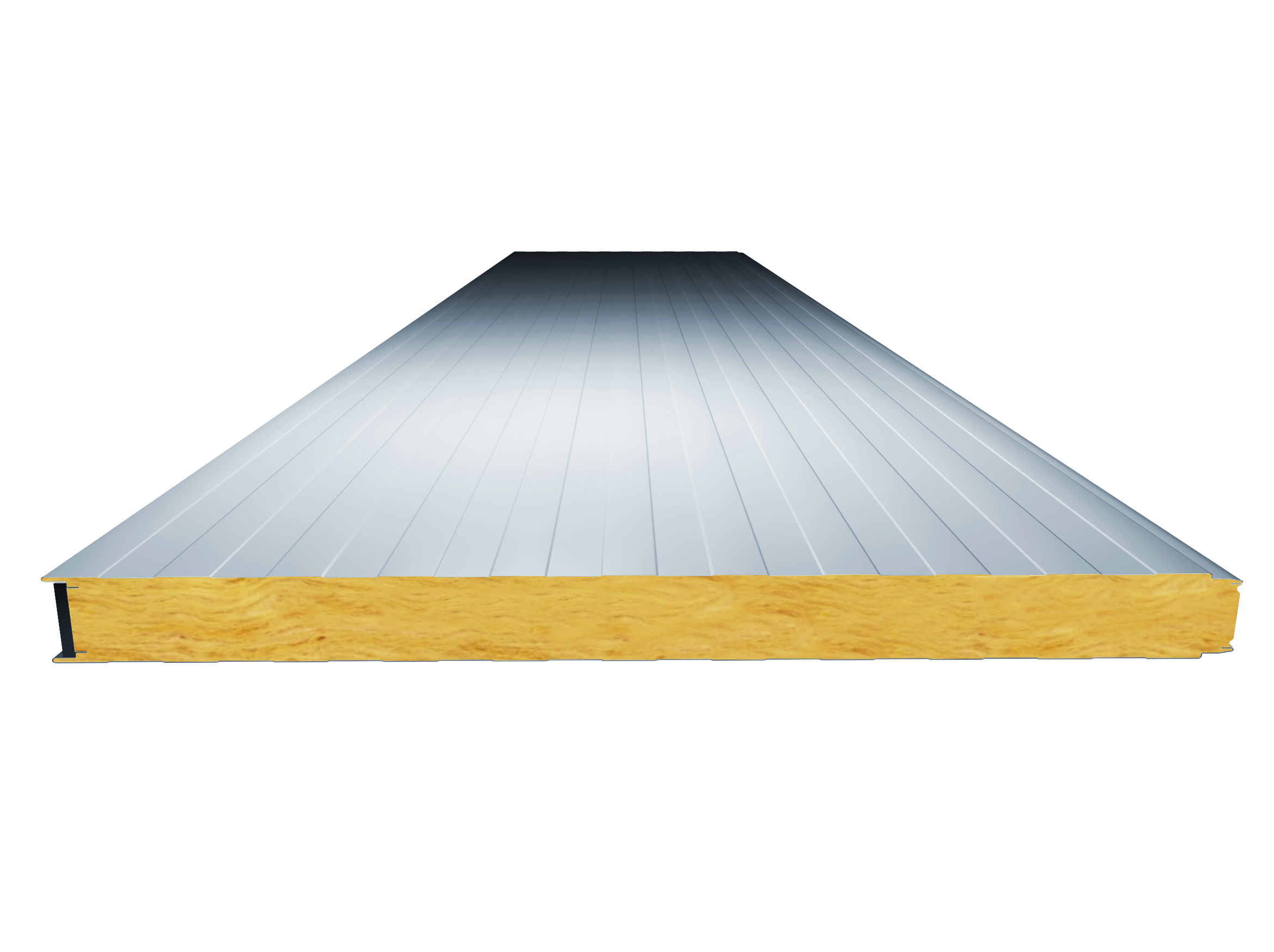

Sandwich panels

Sandwich panels are assembled roof and wall elements that have excellent insulating characteristics thanks to the integration of insulating material. They consist of two thin metal cover sheets, which are shear-resistant and are bonded to one another on an insulated core. The insulated cores normally consist of hard polyurethane foam (PUR), hard polystyrene foam and mineral wool (MW) as well in order to meet the fire prevention requirements.

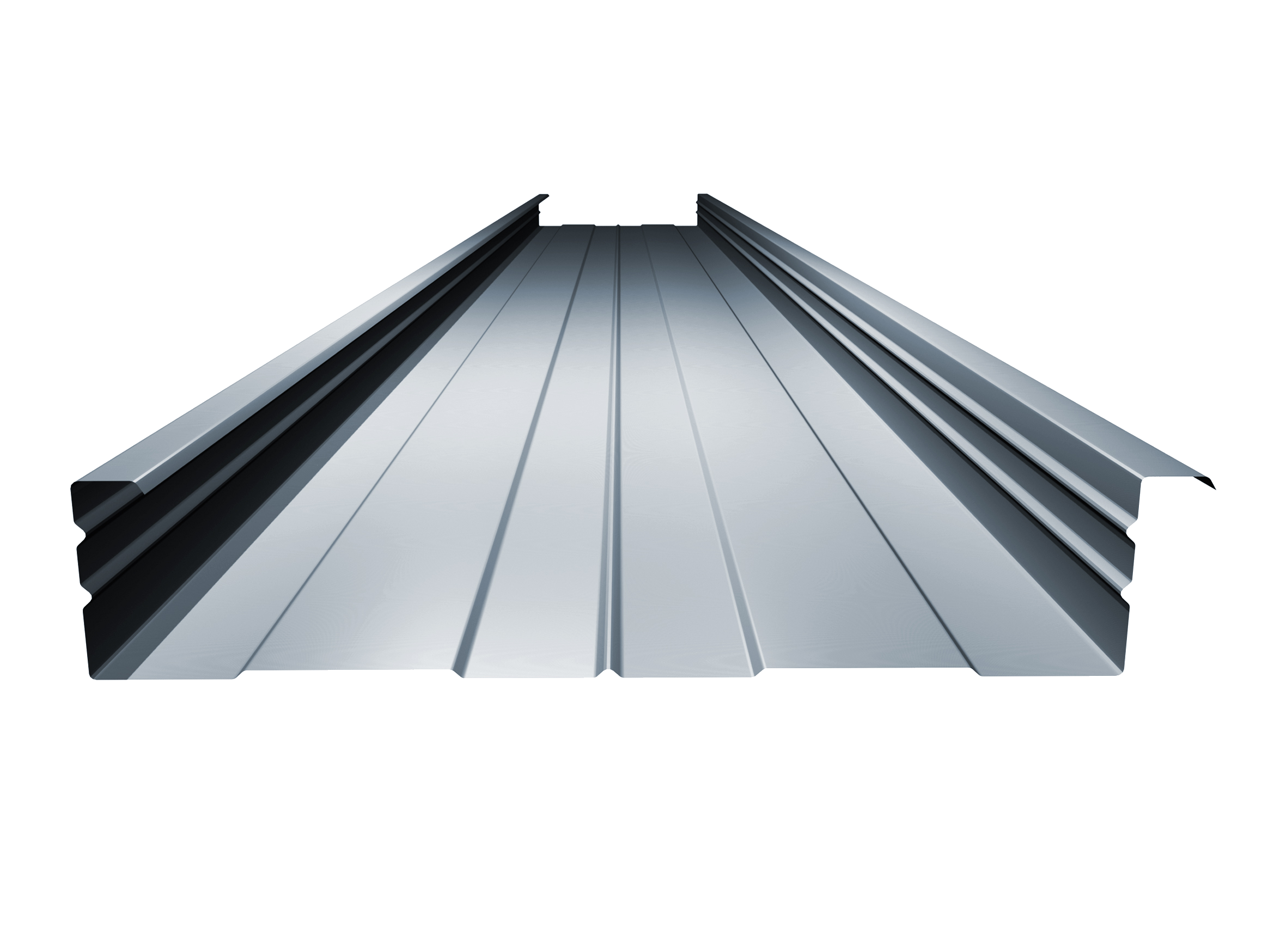

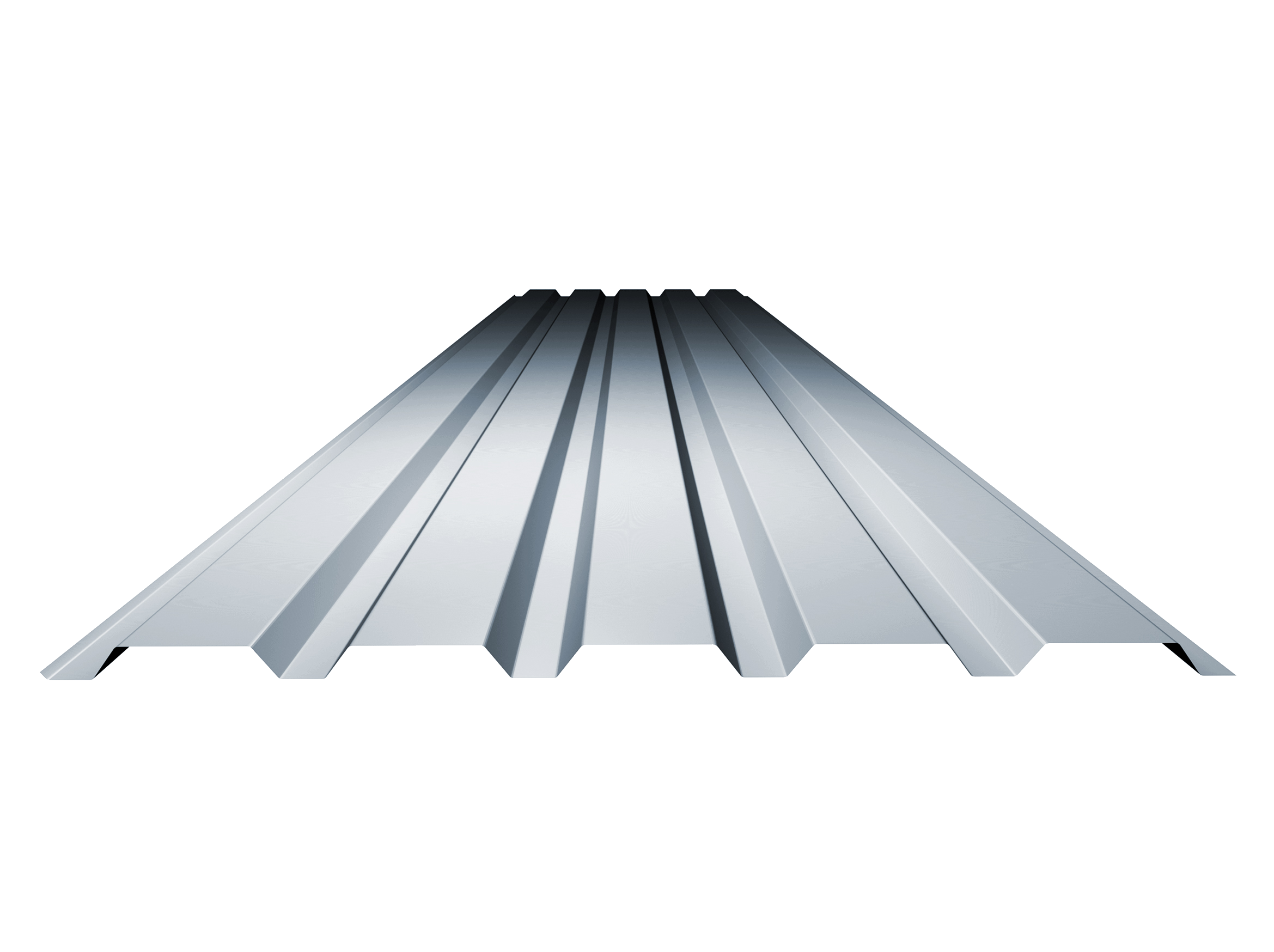

Trapezoidal and corrugated profiles

Trapezoidal profiles are large structural members, which, thanks to the profiling, retain their high load bearing capability. They have been developed from the corrugated profile, which have been known in Europe for around 100 years. Today’s popular characteristic profile shape came to Europe from the USA in the 50s and has steadily and noticeably gained in relevance since about 1960. At the present moment, the proportion of load bearing, room sealing trapezoidal profiles used in the overall area of all new and slightly sloping roofs amounts to 90%.

Liner trays

Liner trays are components that are mainly used as the inner shell in dual-shell wall constructions. They are mainly used in walls today, even though they were originally designed for use in roofs. The measured sound reduction for wall constructions using liner trays has been assessed at an RW of 57 dB. However, a newer product, the sandwich element, is increasingly replacing today’s liner trays constructions.